OUR SERVICES

One shop. Full process.

No loose ends.

We’re built for high-spec, high-stakes manufacturing. We don’t just machine parts — we build peace of mind.

Whether you need a one-off prototype or a fully assembled and finished component, we handle it in-house with speed, accuracy, and accountability. Every job that moves through MSP is inspected and tracked at every stage.

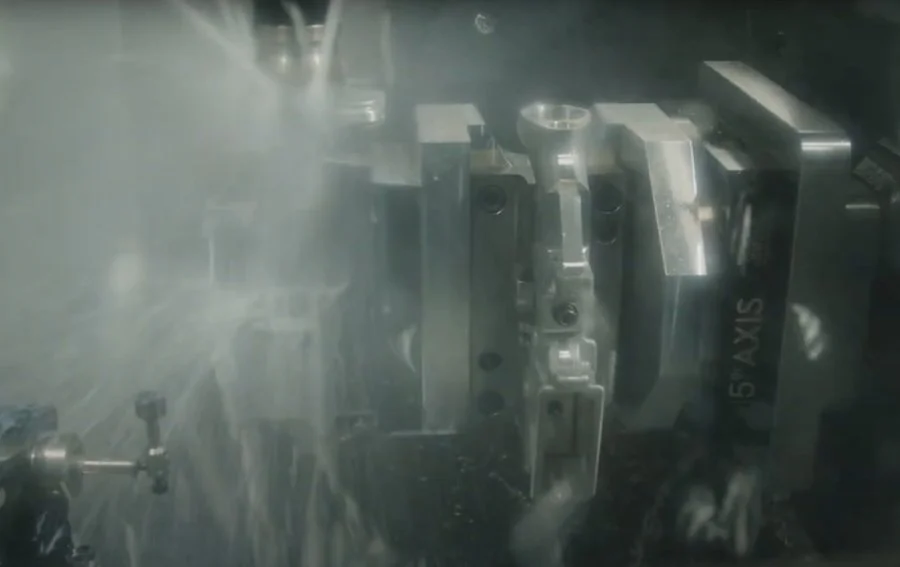

Precision Machining

Our machinists know how to move fast without cutting corners. With CAM software, AI-assisted toolpathing, and deep experience across metals and polymers, we hit the spec the first time—so you don’t waste a second or a dollar on rework. Complex parts don’t scare us. Our machining centers handle everything from single-op prototypes to high-spec, 5-axis parts.

Capabilities Include:

3- and 5-axis CNC milling

6-axis lathe with live tooling

Prototype and production runs

Multi-material work (aluminum, steel, brass, titanium, plastics)

ProShop ERP traceability throughout

Our CAM Assist tool uses AI to reduce programming time by up to 80%, speeding up delivery on complex parts.

Multi-Axis Machining

Using 5-axis machines with pallet changers allows us to produce intricate parts with greater precision and fewer setups. We improve accuracy, reduce handling, and maintain tighter control over critical dimensions by accessing multiple angles in a single operation.

Best for:

Tight-feature geometry

High-value materials (titanium, Inconel, etc.)

Low-volume, high-spec contracts

Reducing fixturing and manual errors

Fabrication & Paint

Fabrication and finishing happen under our roof—not across town. We handle structural welding, prepping, masking, and painting with the same level of detail as our machining.

Capabilities Include:

Weld aluminum and steel structures

Fabricate brackets, enclosures, mounts

Mask and protect critical surfaces

Prep surfaces to paint spec

Apply mil-spec and industrial-grade coatings

Assembly

We don’t just make parts. We build finished products that are fully built, torqued, and ready to go. Whether it’s a single kit or a production run, everything is assembled with precision and consistency. Labeling, part grouping, and packaging are all handled in-house to meet your exact requirements.

Capabilities Include:

Mechanical subassemblies

Hardware install (torque to spec)

Product labeling and packaging

Custom kitting and internal part grouping

Light electromechanical builds (on request)

Inspection at Every Step

Quality isn't a final step—it’s part of the process from start to finish. Every operator on the floor is responsible for in-process checks, and final inspection is performed using calibrated tools, CMMs, and complete documentation. Nothing ships without passing both.

Inspection Includes:

In-process and final inspection

CMM measurements + manual checks

First Article Inspection Reports (FAIR)

Serialized part tracking + full traceability via ProShop ERP

Certificate of Conformance (COC) with every delivery